Product details description

PE Wax for PVC Products

The products in this series are primarily used for PVC pipes, profiles, foam panels, and wire & cable products. Here are their key characteristics:

Functions: They act as dispersants, lubricants, and brighteners in the PVC product forming process.

Demoulding: They exhibit excellent demoulding properties and good fluidity during the PVC product process.

Physical Properties: They do not adversely affect the physical properties of PVC products. Compared to fatty acid lubricants, they have no negative effect on melt tension and VEKA softening point.

Compatibility: They are compatible with extrusion, calendering, and injection molding processes. They improve processing efficiency, prevent adhesion of films, pipes, and sheets, and enhance the smoothness, glossiness, and appearance of the finished product.

Melting Time Control: They can control melting time in specific processing methods. Even when added in large amounts, they maintain good compatibility with other components.

Low Volatility: Due to their high softening point and absence of low melting components, they do not easily precipitate during calendering and sheet extrusion.Technical Data:

| Models |

Product Shape |

Softening Point (℃) |

Viscosity

(CPS) |

Penetration (dmm) |

| B108 |

Powder |

100-105 |

10-15 |

1-2 |

| FM800A |

Powder / Flake |

100-105 |

25-30 |

2-3 |

| BG110A |

Powder |

110-115 |

30-35 |

1-2 |

| S115 |

Powder |

110-115 |

15-20 |

1-2 |

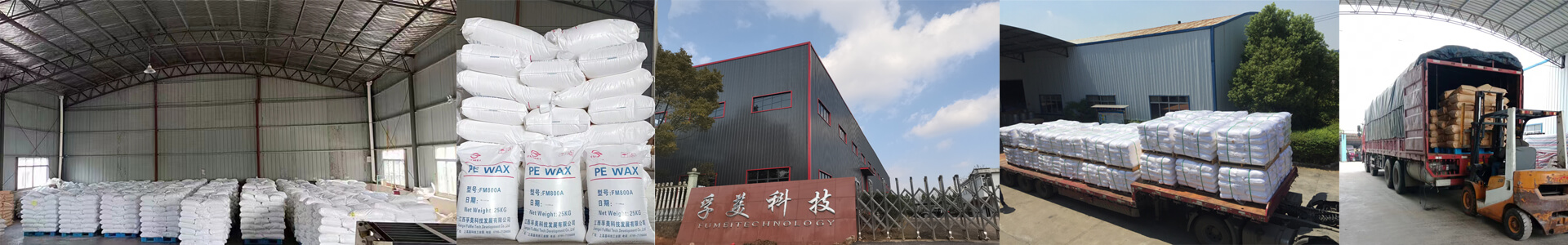

Package and Storage:

Packed in plastic bag, 25kg/bag. Stored in dry places and away from light. Reference additive amount is 0.5%-1%.